Tray sealers

Attractive product presentation, a longer shelf life and better protection during transport: the Tramper Technology tray sealer allows you to seal your product in any type of (sustainable) tray, tub or pot. The various models offer single or double lane packaging and are standardly prepared for MAP packaging. The precision in technology ensures optimal film usage and reduces waste to a minimum. High operational reliability, ease of use and safety make our tray sealing machines a flexible and trustworthy link in your production process!

Less energy, more output

All tray sealers are equipped with servo-controlled drives. Our sealing technique is unique. This technology creates benefits such as adjustable die closing speed, uniform seal quality, low consumption and a higher output.

Customization possible

We ensure that our tray sealers can be integrated seamlessly into a new or existing production environment, whether as a standalone unit or fully automated packaging line. Our tray sealers are fully in line with the industry requirements thanks to the right basic principles, continuous development and close contact with our customers. If our standard tray sealing machines are not suitable, we are happy to come up with a tailor-made solution.

Tray sealers are available in five different standard models:

Type S-340

Type S-360

Type S-560

Type S-580

Type S-5100

Tray Sealing Machine Type S-340

Entry-level traysealer

The Tramper S-340 is the smallest servo controlled fully automatic tray sealing machine. The machine is characterized by its simple but extremely robust construction. With its stainless steel finish, it fully complies with current standards within the food industry.

The traysealer is suitable for processing almost any sealable packaging within the range of 300 x 400 mm. The desired setup is formed by a basic version of the tray sealing machine, which can be fitted with a variety of options.

Furthermore, the S-340 is standardly equipped with a servo controlled film transport system with film break detection and an output belt with knife-edge transitions.

Walking beam

The tray sealing machine is standardly equipped with an infeed conveyor with a length of approximately 2,300 mm. The infeed system is designed as a walking beam transport system with a stroke length of 450 mm, which transports the trays step-by-step and accurately positions the trays. The movement of the walking beam transport system is servo driven and equipped with easily exchangeable tooling for changeovers between different tray sizes.

The transport speed of the infeed conveyor can be freely programmed per product via the controls of the sealing machine.

Features of the S-340

- Quick changeover time – easily exchangeable tooling for quick changeover times

- Compact design – sealing range of 400x300x130 mm (LxWxH)

- User friendly – simple and intuitive operation of the packaging process

This machine is widely used in these industries

- Snacks

- Fruit

- Seafood

Specifications of the tray sealer

- Sealing range: 400 x 300 x 130 mm (LxWxH)

- Capacity: up to 18 cycles per minute

- Suitable for single lane sealing of products in liquid and solid form

- Prepared for Modified Atmosphere Packaging

- Very easily exchangeable tooling due to lightweight die set (<25 kg),

- Accurate movement and easy adjustment and cleaning due to walking beam infeed conveyor

- Optionally available with a separation system in case of random tray supply

- Can be equipped with a tray denester, filling system, product vibrator and lidding system

Tray Sealing Machine Type S-360

Fully automatic tray sealing machine

The S-360 tray sealing machine has a compact and extremely robust construction. With its stainless steel design, it fully complies with the demanding hygienic standards within the food industry. In addition, the S-360 is characterized by excellent ease of use and high achievable capacities.

The tray sealer is suitable for processing almost any sealable packaging within the range 300×600 mm. It lends itself to single lane tray sealing applications for packing a wide range of products, such as fruit and vegetables through to fish, meat, snacks, bakery, poultry, dairy products and ready meals.

The desired setup is formed by a basic version of the tray sealing machine, which can be fitted with a variety of options.

Furthermore, the tray sealing machine is standardly equipped with a servo controlled film transport system with snap detection and a film unwinding reel. A double film reel is optionally available.

Walking beam

The tray sealing machine is standardly equipped with an infeed conveyor with a length of approximately 3,000 mm. The infeed system is designed as a walking beam transport system with a stroke length of 650 mm, which transports the trays step-by-step and accurately positions the trays. The movement of the walking beam transport system is servo driven and equipped with easily exchangeable tooling for changeovers between different tray sizes.

The transport speed of the infeed conveyor can be freely programmed per product via the controls of the sealing machine.

Features of the S-360

- Quick changeover time – less than five minute changeovers with easily exchangeable tooling

- Sealing range of 600x300x130 mm (LxWxH)

- User friendly – easy and intuitive handling of the packaging proces

This machine is widely used in these industries

- Vegetables

- Snacks

- Fruit

- Ready meals

- Dairy

Specifications of the tray sealer

- Sealing range: 600 x 300 x 130 mm (LxWxH)

- Capacity: up to 15 cycles per minute

- Suitable for the sealing of products in liquid and solid form

- Prepared for Modified Atmosphere Packaging

- Suitable for printed, resealable or perforated film

- New 15.6″ user-friendly HMI operator touch screen

- Extremely simple conversion between different tray sizes with quick release tools

- Accurate movement, easy adjustment and easy cleaning due to walking beam conveyor

- Optionally available with a separation system (for random tray supply)

- Can be equipped with a tray denester, filling system, product vibrator and lidding machine

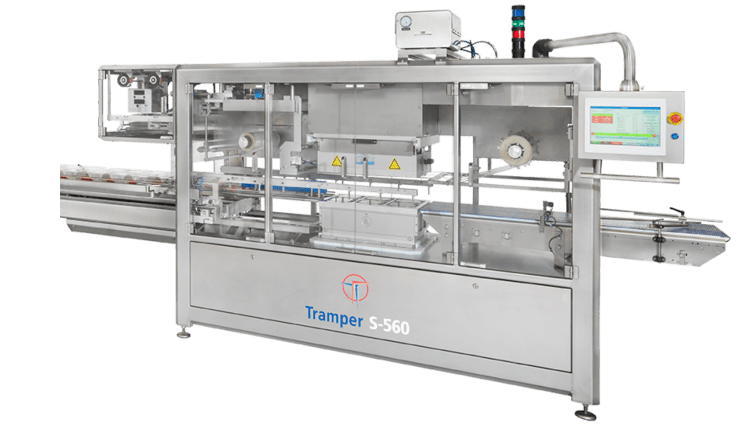

Tray Sealing Machine Type S-560

High-performance traysealer

The Tramper S-560 is a medium to large fully automatic tray sealing machine, which is equipped with servo controlled drives. The machine has a compact and extremely robust construction and, with its stainless steel design, fully complies with the demanding hygienic standards within the food industry. In addition, the S-580 is characterized by excellent ease of use and high achievable capacities.

The tray sealing machine is suitable for processing almost any sealable packaging within the range of 500 x 600 mm. The S-560 lends itself to both single and double lane tray sealing applications for packing a wide range of products, such as fruit and vegetables through to fish, meat, snacks, bakery, poultry, dairy products and ready meals. The desired setup is formed by a basic version of the tray sealing machine, which can be fitted with a variety of options.

Furthermore, the tray sealing machine is standardly equipped with a servo controlled film transport system with break detection and a film unwinding reel. A double film reel is optionally available.

Walking beam

The tray sealing machine is standardly equipped with an infeed conveyor with a length of approximately 3,000 mm. The infeed system is designed as a walking beam transport system with a stroke length of 850 mm, which transports the trays step-by-step and accurately positions the trays. The movement of the walking beam transport system is servo driven and equipped with easily exchangeable tooling for quick changeovers between different tray sizes.

The transport speed of the infeed conveyor can be freely programmed per product via the HMI controls of the sealing machine.

Optionally, an inliner at the end of the tray sealing machine combines the two lanes of trays into a single lane.

Features of the S-560

- Quick changeover time – less than five minute changeovers with easily exchangeable tooling

- Sealing range of 600x500x130 mm (LxWxH)

- User friendly – easy and intuitive handling of the packaging process

Specifications of the tray sealer

- Sealing range: 600 x 500 x 130 mm (LxWxH)

- Capacity: up to 15 cycles per minute

- Suitable for the tray sealing of products in liquid and solid form

- Prepared for Modified Atmosphere Packaging

- User-friendly HMI operator touch screen

- Suitable for single and double lane packaging

- Possibility for further automation with a tray denester, filling station and lidding system

- Machine can be equipped with an integrated labelling machine, printer and additional film reel for quick film changes

This machine is widely used in these industries

-

Vegetables

-

Meat

- Ready meals

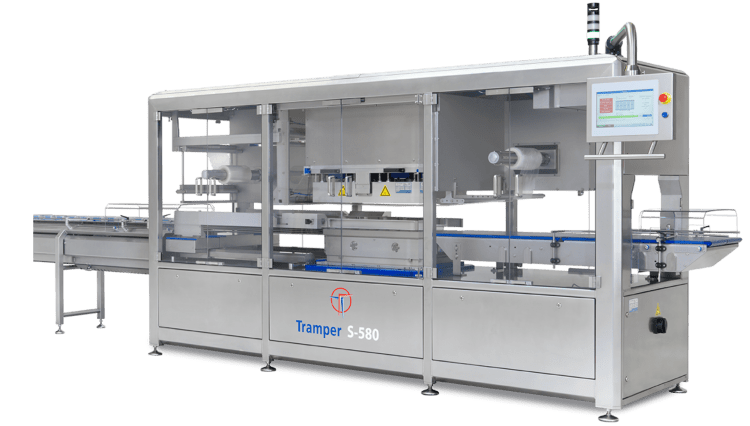

Tray Sealing Machine Type S-580

High-output tray sealer

The Tramper S-580 is a large fully automatic tray sealing machine, which is equipped with servo controlled drives. The machine has a compact and extremely robust construction and, with its stainless steel design, fully complies with the demanding hygienic standards within the food industry. In addition, the S-580 is characterized by excellent ease of use and high achievable capacities.

The tray sealing machine is suitable for processing almost any sealable packaging within the range of 500 x 800 mm. The S-580 lends itself to both single and double lane tray sealing applications. The desired setup is formed by a basic version of the tray sealing machine, which can be fitted with a variety of options.

Furthermore, the tray sealing machine is standardly equipped with a servo controlled film transport system with break detection and a film unwinding reel. A double film reel is optionally available.

Walking beam

The tray sealing machine is standardly equipped with an infeed conveyor with a length of approximately 3,800 mm. The infeed system is designed as a walking beam transport system with a stroke length of 850 mm, which transports the trays step-by-step and accurately positions the trays. The movement of the walking beam transport system is servo driven and equipped with easily exchangeable tooling for changeovers between different tray sizes.

The transport speed of the infeed conveyor can be freely programmed per product via the controls of the sealing machine.

Optionally, an inliner at the end of the tray sealing machine combines the two lanes of trays into a single lane.

Features of the S-580

- Quick changeover time – easily exchangeable tooling for quick changeover times

- Large sealing range of 800x500x130 mm (LxWxH)

- User friendly – easy and intuitive handling of the packaging process

Specifications of the tray sealer

- Sealing range: 800 x 500 x 130 mm (LxWxH)

- Capacity: up to 14 cycles per minute

- Suitable for the sealing of products in liquid and solid form

- Prepared for Modified Atmosphere Packaging

- Suitable for single and double lane packaging

- Optionally available with separation system (for random tray supply)

- Possibility for further automation with a tray denester, filling system and lidding system

- Can be equipped with an integrated labelling machine, printer and additional film reel for quick film changes

This machine is widely used in these industries

- Meat

- Snacks

- Meat substitutes

- Seafood

- Bakery

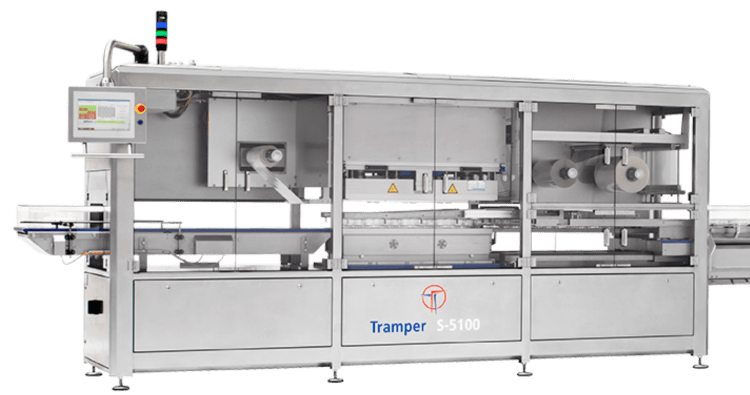

Tray Sealing Machine Type S-5100

Large tray sealing machine

The Tramper S-5100 is a large fully automatic tray sealing machine, which is equipped with servo controlled drives. The machine has a compact and extremely robust construction and, with its stainless steel design, fully complies with the demanding hygienic standards within the food industry. In addition, the tray sealer is characterized by excellent ease of use and high achievable capacities.

The tray sealing machine is suitable for processing almost any sealable packaging within the range of 500 x 1,000 mm. The S-5100 lends itself to both single and double lane tray sealing applications. The desired setup is formed by a basic version of the tray sealing machine, which can be fitted with a variety of options.

Furthermore, the tray sealing machine is standardly equipped with a servo controlled film transport system with break detection and a double film unwinding reel.

Walking beam

The tray sealing machine is standardly equipped with an infeed conveyor with a length of approximately 4,000 mm. The infeed system is designed as a walking beam transport system with a stroke length of 1050 mm, which transports the trays step-by-step and accurately positions the trays. The movement of the walking beam transport system is servo driven and equipped with easily exchangeable tooling for changeovers between different tray sizes.

The transport speed of the infeed conveyor can be freely programmed per product via the controls of the sealing machine. Optionally, an inliner at the end of the tray sealing machine combines the two lanes of trays into a single lane.

Features of the S-5100

- Quick changeover time – easily exchangeable tooling for quick changeover times

- Large sealing range of 1,000x500x130 mm (LxWxH)

- User friendly – easy and intuitive handling of the packaging process

Specifications of the tray sealer

- Sealing range: 1000 x 500 x 130 mm (LxWxH)

- Capacity: up to 14 cycles per minute

- Suitable for the sealing of products in liquid and solid form

- Prepared for Modified Atmosphere Packaging

- Suitable for single and double lane packaging

- Further automation with a tray denester, filling station and lidding system

- Suitable for complete built-in integration of labelling machine and printer

- Can be equipped with an integrated labelling machine and printer

- Standardly equipped with double film reel for quick film changes

This machine is widely used in these industries

- Meat

- Ready meals

- Meat substitutes

- Bakery