Lidding system

You want to be able to store food that you do not consume completely immediately. A lid takes care of that! Tramper Technology’s lidding machines are used to put lids onto sealed trays. This ensures that the food can be consumed in several stages, but it also makes the product recognizable!

Optimal closure

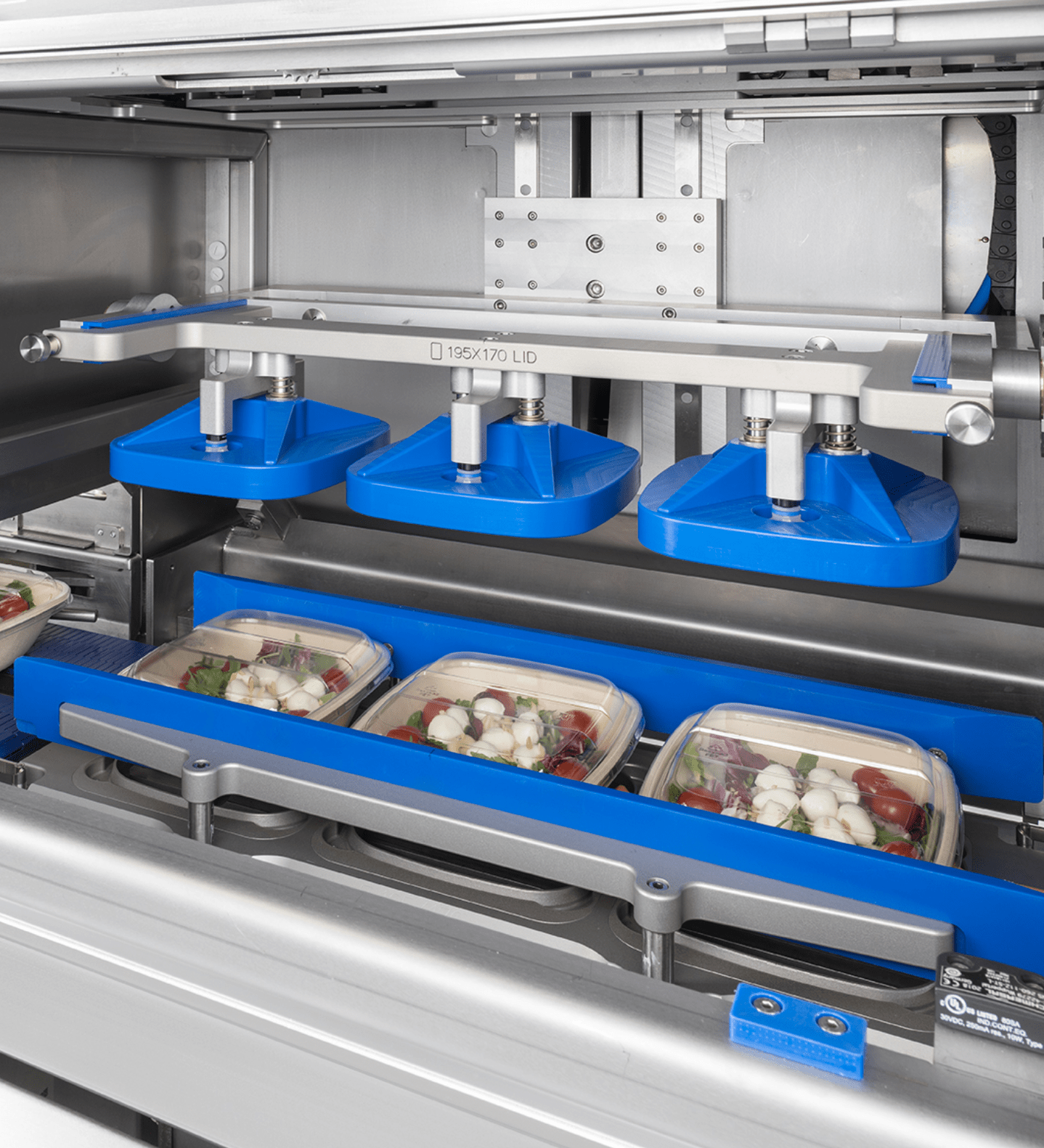

Tramper Technology’s lidding systems are servo controlled and consist of a denester and a transport system with an integrated tray support unit. This means that the position of both the tray and the lid can be precisely aligned. This is crucial for a good closure! Thanks to the easily interchangeable tooling, changeover times are quick. The lidder systems are suitable for single and multiple lids simultaneously and can be supplied as a single or double-lane system.

Standard or customized

Our lidding systems fit seamlessly into new or existing production environments. Not only as a stand alone unit, but also as a fully automated packaging line.

Your wishes are always our point of departure. So if the standard solution is not suitable, we are happy to think along about a customized alternative.

Lidding systems are available in two different standard models:

Stand-alone lidding

Integrated lidding

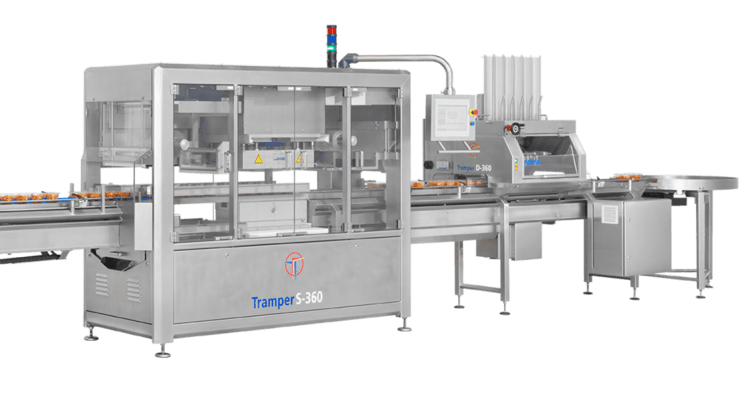

Stand-alone lidding

Stand-alone lidding

If you want to be absolutely sure that your reclosable packaging is properly closed, choose for our stand-alone lidding system. The stand-alone lidding units are particularly suitable if the trays are not supplied by a Tramper packaging line. For example, when trays are filled manually or when the trays are exiting a thermoformer.

In case of random delivery of (thermoforming) packaging, the standard lid system is equipped with a separation system. This system places the packages on the correct pitch for the lidding machine.

In order to lid accurately, a tray support unit is placed below the lidding unit with a combination of a centering and fixation system. It centres and secures each tray individually before the lid is positioned and applied

.

Specifications of the lidding system

- Two lidding range options: 600 x 300 mm or 800 x 320 mm

- Smart servo-controlled system

- Used for single and double lane lidding

- Easily exchangeable tooling for quick changeover times

This machine is widely used in these industries

- Dairy

- Bakery

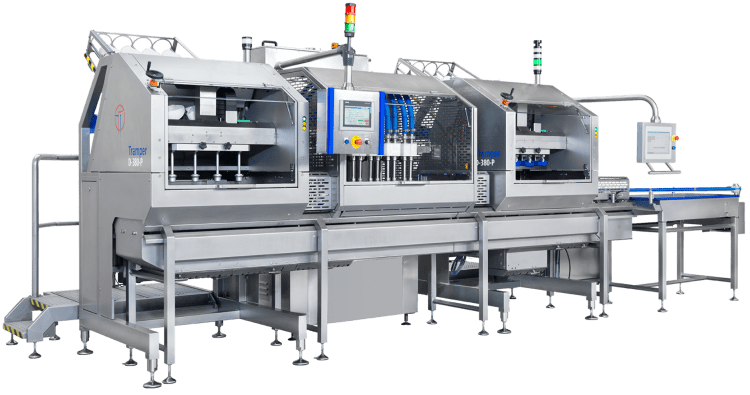

Integrated lidding

Reclosable packaging

With a servo controlled lidding solution, you can be sure that your reclosable packaging is properly closed. With our lidding system integrated into a Tramper packaging line, the position of trays in relation to the lids is always aligned precisely. The supply of trays to the lidding system is precisely coordinated on the correct pitch by our walking beam transport system.

This solution is suitable for single and multiple lidding and can be used on both a single and double lane packaging lines. The machine is standardly equipped with a product memory for storing product settings. In combination with the easily exchangeable tooling, this ensures quick changeover times.

Specifications of the lidding system

- Two lidding range options: 600 x 300 mm or 800 x 300 mm

- Smart servo-controlled system

- Used for single and double lane lidding

- Easily exchangeable tooling for quick changeover time

This machine is widely used in these industries

- Snacks

- Dairy