Filling solutions

If you need a high-quality dosing and filling system, Tramper Technology’s machines are suitable for a precise transfer of products from the weigher to the packaging. The products are accurately portioned, divided and filled into your packaging simultaneously, which greatly increases the line capacity.

The machines can be expanded with a variety of options. For example, leafy vegetables can be pressed or tamped down. This ensures that the packaging is used optimally and that the product remains below the edge of the tray.

Fragile products

Minimal drop heights and a fully controlled filling pattern are crucial for many fragile products. Our filling systems have been developed in such a way that products from the (multihead or linear) weigher are carefully transferred to the packaging.

The automatic height adjustment makes the processing and filling of different tray heights easy.

Customized machine

Our filling solutions are fully in line with the industry requirements. If the standard filling system is not suitable for your needs, customization is surely possible.

Accurate process

The servo-controlled movements ensure a uniform and accurate distribution and filling process. Thanks to the utmost precision in technology, waste by spillage or contamination by human contact is minimal. This means that these machines meet the highest hygiene requirements. These filling systems are also easy to clean.

With the easily interchangeable tooling, you can quickly change over to other products or packaging.

Filling systems are available in three different standard models:

Filling system, Type F-360

Filling system, type F-560

Filling system, type F-580

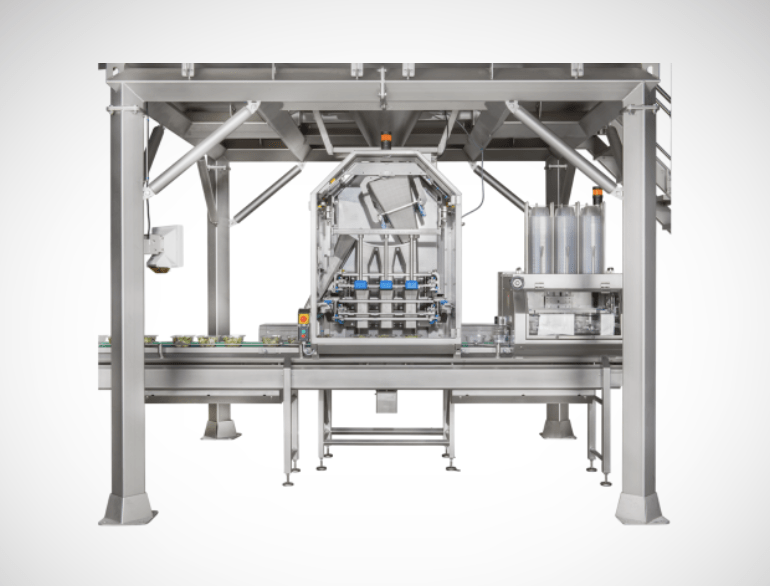

Filling system Type F-360

Accurate filling

The F-360 filling system ensures the accurate distribution of the portions from the multihead weigher to the trays on the single lane conveyor.

A servo driven swiveling funnel distributes the portions between the buffer hoppers. From the buffer hoppers, the portions are transferred into the filling hoppers. The filling hoppers are then positioned horizontally (servo controlled) above the trays on the transportation system. When the trays are ready on the transportation system, the filling hoppers are positioned just above or into the trays with a vertical movement. Next, the filling hoppers are emptied and the product is (optionally) pressed into the tray with a servo controlled pressing/tamping unit. Then a new cycle starts again.

The tooling is very easy to change. This makes a quick changeover between different tray sizes possible.

The machine is extremely suitable for single-lane filling of solid products, such as (mixed) vegetables, mussels, shrimps, olives, shawarma, chicken fillets, ground meat and other food types.

Features of the F-360

- Quick changeover time – converting to another packaging size within 5 minutes

- Easy to clean thanks to its hygienic and accessible design

- High capacity while maintaining a manageable filling pattern

This machine is widely used in these industries

- Vegetables

- Snacks

- Fruit

- Seafood

Specifications of the filling system

- Version: single lane

- Product supply points (weigher): 1

- Filling points: 2 – 6

- Portion size: 30 – 4000 grams

- Filling range: standard 600 x 300 x 130 mm (LxWxH)

- Capacity: up to 18 cycles per minute (product dependent)

- Can be equipped with an integrated pressing/tamping system

- Optionally equipped with a reject hopper for discharging incorrect weights or remaining product at the end of a batch

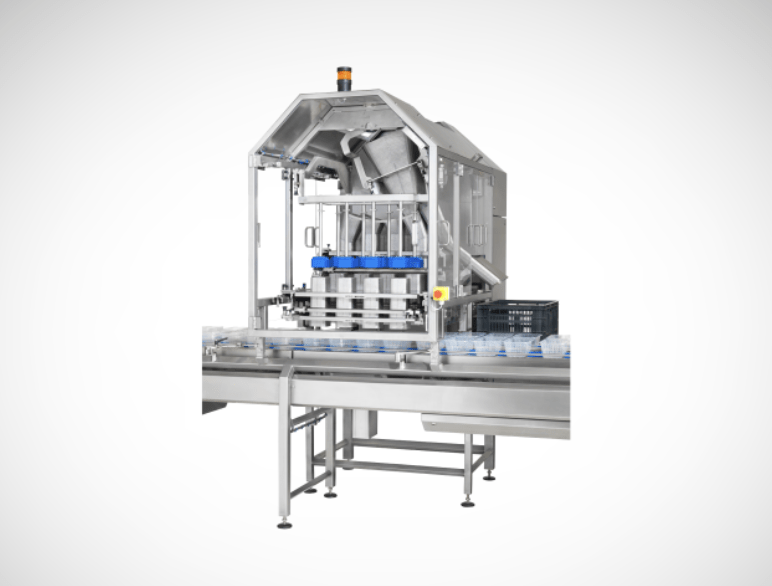

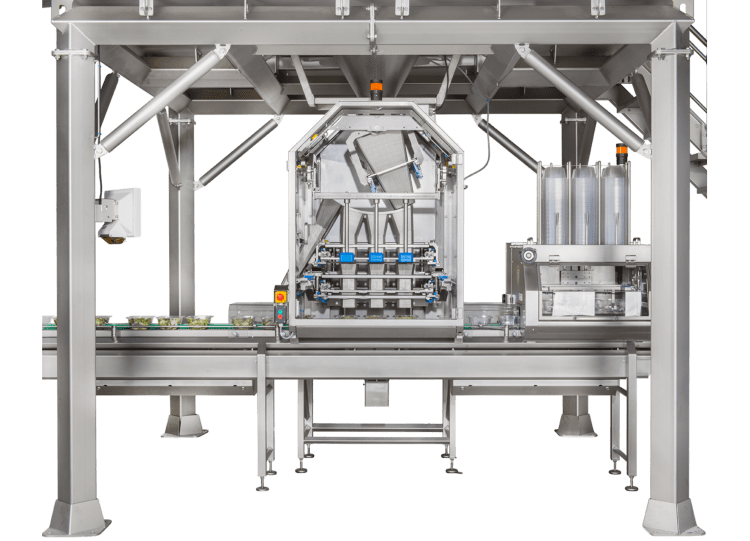

Filling system Type F-560

Servo controlled filling

The F-560 filling system ensures the accurate distribution of the portions from the multihead weigher to the trays on the single our double lane conveyor.

A servo driven swiveling funnel distributes the portions between the buffer hoppers. From the buffer hoppers, the portions are transferred into the filling hoppers. The filling hoppers are then positioned horizontally (servo controlled) above the trays on the transportation system. When the trays are ready on the transportation system, the filling hoppers are positioned just above or into the trays with a vertical movement. Next, the filling hoppers are emptied and the product is (optionally) pressed into the tray with a servo controlled pressing/tamping unit. Then a new cycle starts again.

The tooling is very easy to change. This makes a quick changeover between different tray sizes possible.

The machine is extremely suitable for single or double lane filling of solid products, such as (mixed) vegetables, mussels, shrimps, olives, nuts, chicken fillets, meatballs and other food types.

Features of the F-560

- Filling range – 600x500x130, suitable for single and double lane filling

- Easy to clean thanks to its hygienic and accessible design

- High capacity while maintaining a manageable filling pattern

This machine is widely used in these industries

- Meat

- Vegetables

- Ready meals

- Meat substitutes

Specifications of the filling system

- Version: single or double lane

- Product supply points (weigher): 1 or 2

- Filling points: 2 – 12 (depending on tray size)

- Portion size: 30 – 4000 grams

- Filling range: standard 600 x 500 x 130 mm (LxWxH)

- Capacity: up to 18 cycles per minute (product dependent)

- Can be equipped with an integrated pressing/tamping system

- Optionally equipped with a reject hopper for discharging incorrect weights or remaining product at the end of a batch

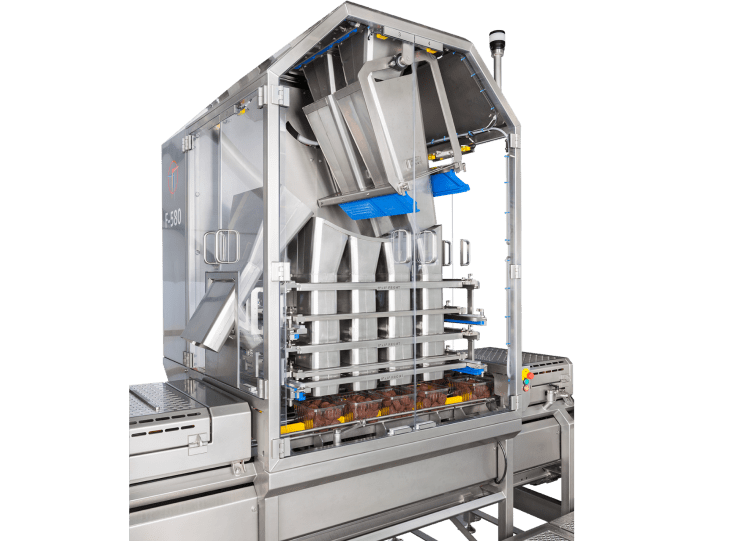

Filling system Type F-580

Double lane filling

The F-580 filling system ensures the accurate distribution of the portions from the multihead weigher to the trays on the double lane conveyor.

A servo driven swiveling funnel distributes the portions between the buffer hoppers. From the buffer hoppers, the portions are transferred into the filling hoppers. The filling hoppers are then positioned horizontally (servo controlled) above the trays on the transportation system. When the trays are ready on the transportation system, the filling hoppers are positioned just above or into the trays with a vertical movement. Next, the filling hoppers are emptied and the product is (optionally) pressed into the tray with a servo controlled pressing/tamping unit. Then a new cycle starts again.

The tooling is very easy to change. This makes a quick changeover between different tray sizes possible.

The machine is extremely suitable for double lane filling of solid products, such as (mixed) vegetables, mussels, shrimps, olives, nuts, chicken fillets, meatballs and other food types.

Features of the F-580

-

Quick changeover time – converting to another packaging size within 5 minutes

-

Easy to clean thanks to its hygienic and accessible design

- High capacity while maintaining a manageable filling pattern

This machine is widely used in these industries

- Snacks

- Bakery

- Meat substitutes

Specifications of the filling system

- Version: double lane

- Product supply points (weigher): 1 or 2

- Filling points: 2 – 14

- Portion size: 30 – 4000 grams

- Filling range: standard 800 x 500 x 130 (LxWxH in mm)

- Capacity: up to 18 cycles per minute (product dependent)

- Can be equipped with an integrated pressing/tamping system

- Optionally equipped with a reject hopper for discharging incorrect weights or remaining product at the end of a batch