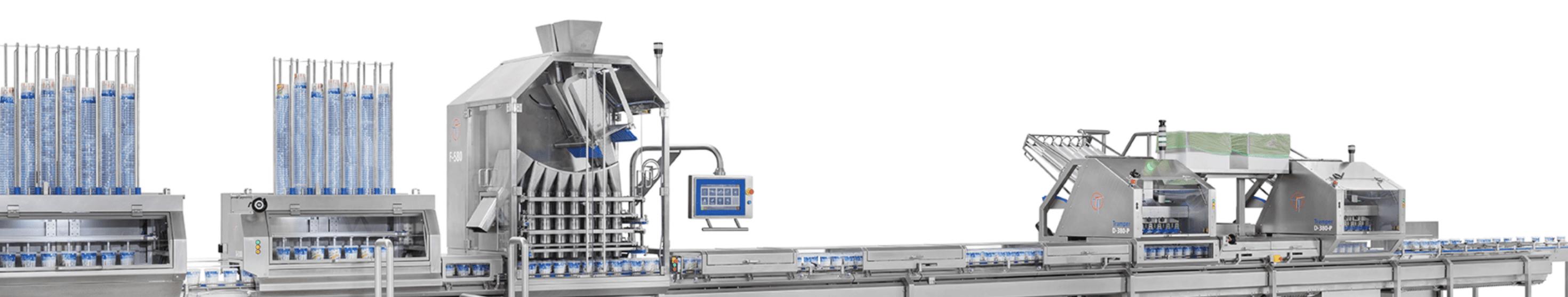

Denesting systems

If you are looking for high-quality denesting systems that are suitable for destacking tubs, trays, pots, blisters and lids made of various materials at high speeds, we have the right solution! Whether you are looking to denest one or sixteen units at a time; our denesters surpass the highest requirements in terms of hygiene, flexibility and accuracy. The denested packages are placed on the transport system, which is situated below the machine.

High capacity

Thanks to the servo-controlled movements, the denesting systems can operate at high capacities. Switching between different types of packaging is easy: you don’t need any tools and it only takes a few minutes!

Customization possible

With the right basic principles, continuous development and close contact with our customers, our denesters are fully in line with the industry requirements. If the standard solutions are not suitable, a customized solution is surely possible.

Denesting systems come in three different standard models:

Tray Denester, Type D-360

Tray Denester, type D-3100

Tray Denester, type D-380-P

Tray denester Type D-360

Servo controlled denesting

The D-360 tray denester is a servo controlled denester with an available denesting surface of 300 x 600 mm. It is suitable for single or multiple denesting of trays with one or more compartments. The size of the tray or the required pitch on which the trays must be delivered to the packaging line determine the amount of trays that are denested per cycle.

The tooling is very easy to exchange, which makes a very quick changeover between different tray sizes possible.

Features of the D-360

- Quick changeover time – easily exchangeable tooling for quick changeover times

- Denesting range – 600 x 300 mm

- High speed – 20-30 cycles per minute/200-300 packs per minute (depending on the tray size)

This machine is widely used in these industries

- Meat

- Vegetables

- Fruit

- Dairy

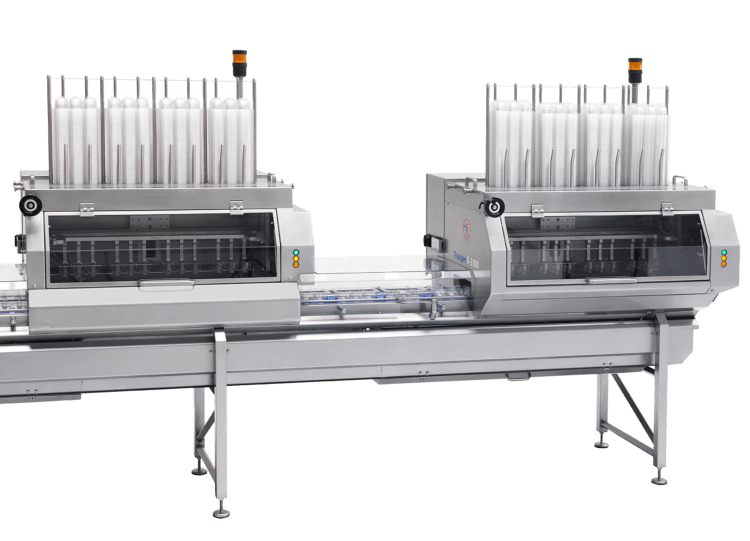

Tray denester Type D-3100

Servo controlled denesting

The D-3100 tray denester is a servo controlled denester with an available denesting surface of 300 x 1000 mm. It is suitable for single or multiple denesting of trays with one or more compartments. The size of the tray or the required pitch on which the trays must be delivered to the packaging line determine the amount of trays that are denested per cycle.

The tooling is very easy to exchange, which makes a very quick changeover between different tray sizes possible.

Features of the D-3100

- Quick changeover time – easily exchangeable tooling for quick changeover times

- Denesting range – 1000 x 300 mm

- High speed – 220-30 cycles per minute/200-300 packs per minute (depending on the tray size)

This machine is widely used in these industries

- Meat

- Meat substitutes

- Seafood

- Bakery

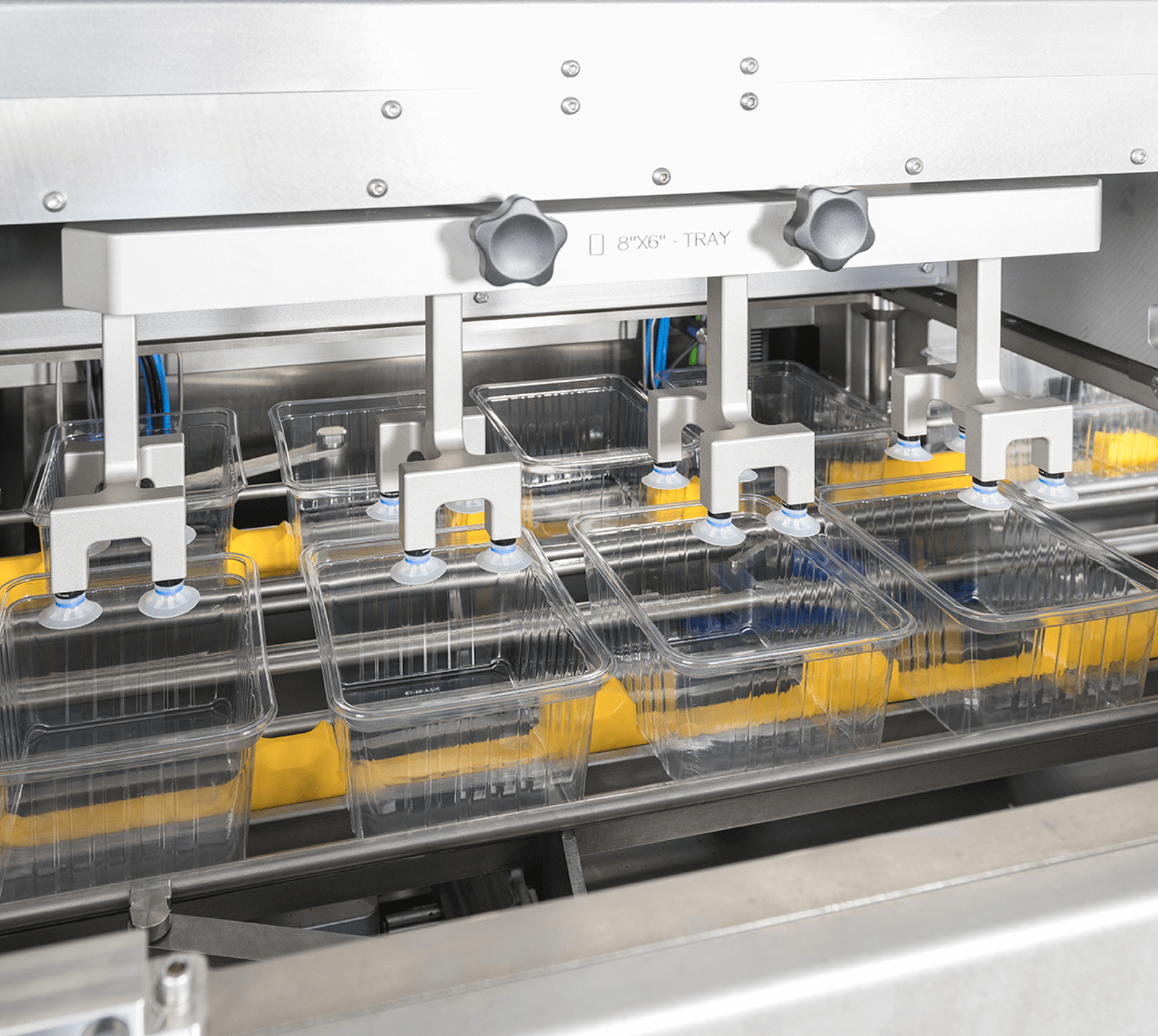

Tray denester Type D-380-P

Servo controlled denesting and lidding

The Tramper D-380-P is a servo-controlled denester with an available denesting range of 300 x 800 mm. The machine is suitable for single or multiple denesting and positioning of a broad range of trays or lids. The size of the tray or lid or the required pitch on which the trays must be delivered to the packaging line determine the amount of trays or lids that are denested per cycle.

The machine can also be used as a lidding machine, particularly when dealing with lids which require a fair amount of force to be closed properly.

The tooling is very easy to exchange, which makes a very quick changeover between different tray sizes possible.

Features of the D-380-P

- Quick changeover time – easily exchangeable tooling for quick changeover times

- Denesting range – 800 x 320 mm

- High speed – 220-30 cycles per minute/200-300 packs per minute (depending on the tray size)

This machine is widely used in these industries

- Ready meals

- Dairy

- Bakery