Horizontal Flowpackers

Selo Nordic, your trusted partner in packaging machinery, offers versatile and advanced horizontal flowpackers specifically designed for the food industry among many other industries. These machines ensure fast, reliable, and hygienic packaging, meet food industry quality standards, and empower you to take your packaging process to the next level.

Why choose horizontal flowpacker?

- European quality: Designed and manufactured in the Netherlands with high-quality components from Siemens, Leze, and Festo.

- Advanced technology: Suitable for MAP gas flushing applications with excellent hermetic closed seals.

- Hygienic design: Stainless steel construction, making it suitable for harsh industry environments and compllant with HACCP regulations

- Customized solutions: Various accessories available, such as infeed systems, printers, labellers, reject devices, etc.

- Expert advice: Benefit from our years of experience and let our specialists advise you

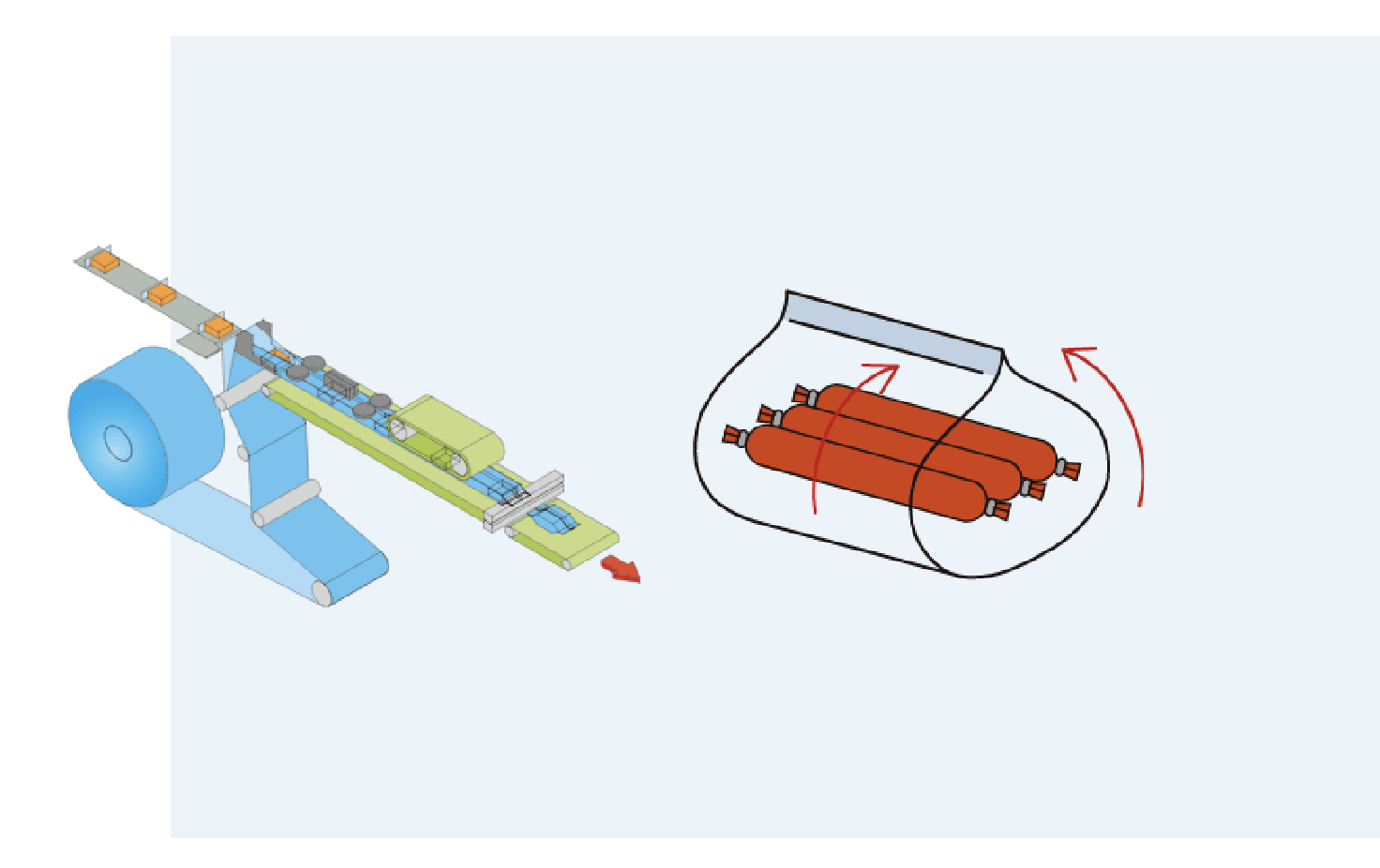

Top Seal Flowpacker:

A top seal flowpacker, also known as a “bottom film” machine, applies the sealing from the top of the product.

Here are some key features and benefits:

- Compact design: Requires less headspace, leading to a potentially smaller machine footprint.

- Can be more efficient for products with loose particles that might fall out.

- The product is directly carried and supported by the foil.

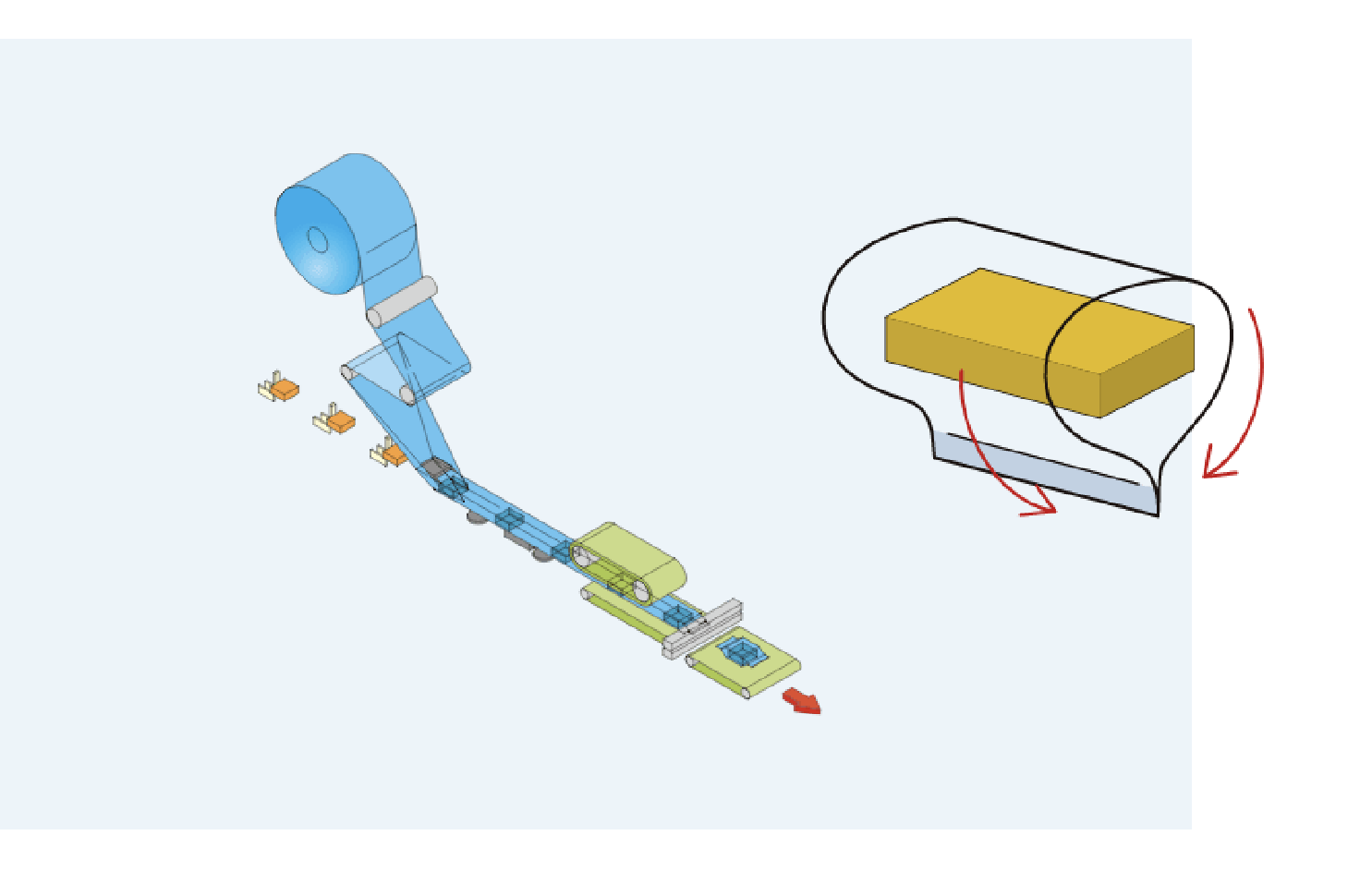

Bottom Seal Flowpacker:

A bottom seal flowpacker, also known as a “top film” machine, applies the sealing at the bottom of the product.

Here are some key features and benefits:

- Ideal for products requiring a flat presentation on the shelf, like bakery items or fresh produce trays.

- Offers greater visual appeal as the product is showcased facing no centerseals

- Suitable for products that need stability and a flat base for stacking, like boxes or pouches.

- Often the preferred choice for products with delicate contents as the bottom seal provides additional support

Flowpackers can for example be used for:

- Meat beef / Pork / Poultry /

- Sliced meat, cheese

- Fish

- Bread

- Cheese – Dairy

- Fresh Vegetables

- Ready Meals

- Snacks

- Laundry / Textile