SAUCE INSTALLATIONS

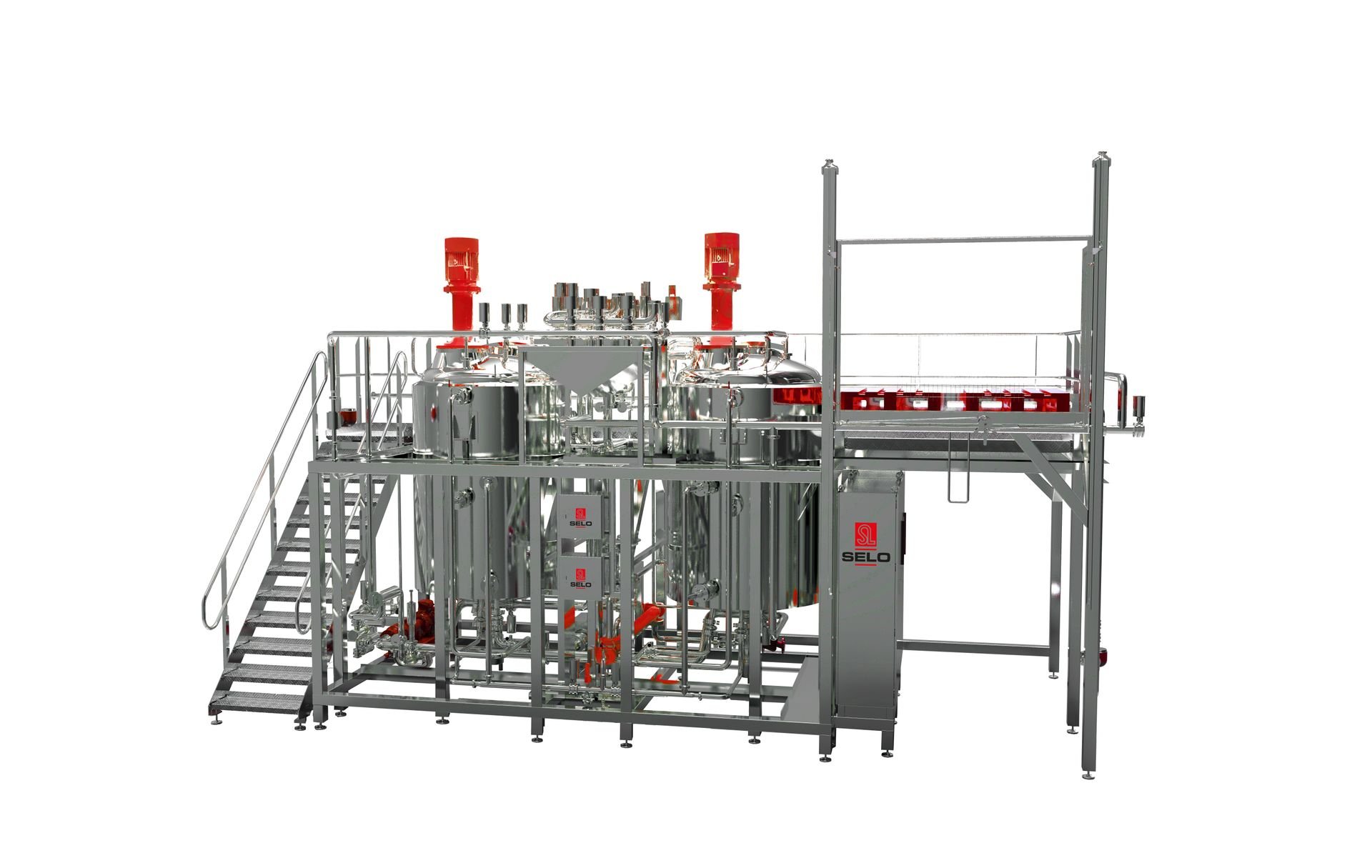

At Selo, we strive for nothing less than perfection in the world of sauces with our sauce installations. For our fully automatic process and production lines for cooked, pasteurized, and chilled sauces, we always uphold the highest standards of hygiene and quality. With our years of experience and dedication in this industry, we are well-positioned to respond to developments in the world of sauces.

What sets our sauce installations apart is our expertise in producing a range of sauces, such as pizza sauce, pasta sauce, spaghetti sauce, and meat/vegetable sauces, with or without chunks. Our installations are designed not only to meet high food quality standards but also to excel in efficiency. Just like with our other production lines, we optimize and automate every aspect of the production process, allowing you to effortlessly produce high-quality sauces in various flavors and variations, always with precise portions.

SAUCE PRODUCTION LINES WITH FAST AND EFFECTIVE RECIPE CHANGES

Did you know that our sauce production lines have even more significant features? Consider the quick and effective recipe change. With our sauce installations, switching recipes is fast and easy. This allows you to produce not only a variety of sauces but also other liquid food products, such as soups or dressings, with the same precision and quality. We understand that packaging sauces is crucial, so we also offer advice and solutions tailored to your needs. This includes modern packaging machines for stand-up pouches, hermetically sealed jars, and bottles, all designed to meet the strictest standards of the food industry.

At Selo, we believe that every production line has unique needs, including yours. That’s why a team of experienced engineers works closely with you to create a customized sauce production line tailored to your specific requirements. If you already have an existing production line, we are here to help you optimize your production process. Furthermore, at Selo, we continuously develop and innovate our machines to provide you with the latest technologies and automation systems. This way, you can continue to produce optimally and efficiently, and excel in your industry.

OPTIONALLY, THE FOLLOWING COMPONENTS CAN BE INTEGRATED:

- Direct steam injection

- Pressure/vacuum cooling

- Homogenizer

BENEFITS OF SAUCE INSTALLATION FROM SELO

Selo’s sauce installation offers a range of benefits that optimize your production process and take your products to the next level. We are committed to delivering nothing less than quality, which translates into more efficient and high-quality products. Our machines and plant components are of high quality and meet the strictest production standards. But it doesn’t stop there; we are equally committed to maintaining production line reliability in all its functions. In addition to quality, we offer a range of other important benefits:

Safety: We test our production lines in every detail for safety, both for the products and for the production process itself.

Increased efficiency: Our advanced production lines allow your plant to operate more efficiently and effectively, resulting in higher production levels, lower costs and improved profitability.

Improved portion accuracy: Our sauce plants are designed to operate with greater precision and speed. We continuously monitor production accuracy and immediately identify any discrepancies, minimizing waste and increasing production efficiency.

Seamless connection to packaging process: Our production lines can be seamlessly integrated with various packaging processes, keeping your workflow running smoothly and efficiently.

With sauce installation from Selo, we assure you of a production process that meets the highest standards of quality and reliability. You can rely on safe, efficient and highly accurate production while taking your business to new heights.

SELO’S APPROACH TO SAUCE INSTALLATIONS

At Selo, quality and efficiency are central to the design and installation of sauce installations, taking into account the highest hygiene requirements in the food industry. Our approach begins with a thorough inventory of your specific needs and requirements. We want to know everything from the desired speed of recipe changes to the ability to produce both chilled and hot sauces, with the ease of operation by your entire production team. We will present to you the capabilities of our machines and invite you to see them in action at our Technology Center.

Once we have gathered all the necessary information, our dedicated engineering team sets to work. With their technical expertise and extensive experience in the food industry, they translate your requirements into a thoughtful and comprehensive sauce installation.

In our workshop, the approved sauce installation is assembled. Each component is precisely placed and functionally assembled. This is where both the hardware and software come together and undergo extensive testing to ensure that the sauce plant meets the strictest quality standards. After thorough inspections, the sauce plant is ready for shipment to your plant.

Our experienced technicians install the sauce installation with utmost care in your factory hall. They ensure that everything works perfectly, exactly as agreed. Before official production begins, your operations team receives hands-on training to become familiar with the new installation. Once everything is ready and your team is ready to start, you can seamlessly produce high-quality sauces. With Selo, you have the perfect partner for your sauce production process.

PRODUCING VARIOUS SAUCES

The production of sauces requires attention to detail. Producers must prioritize hygiene, quality, and efficiency. This involves meeting strict food safety standards, maintaining the integrity of recipes, and achieving consistent taste and texture. Additionally, flexibility is essential to quickly adapt to changing consumer demands. Innovative technologies and automated systems play a crucial role in ensuring a successful sauce production process, while still focusing on delivering high-quality products that meet consumer expectations.