JAM PRODUCTION LINE

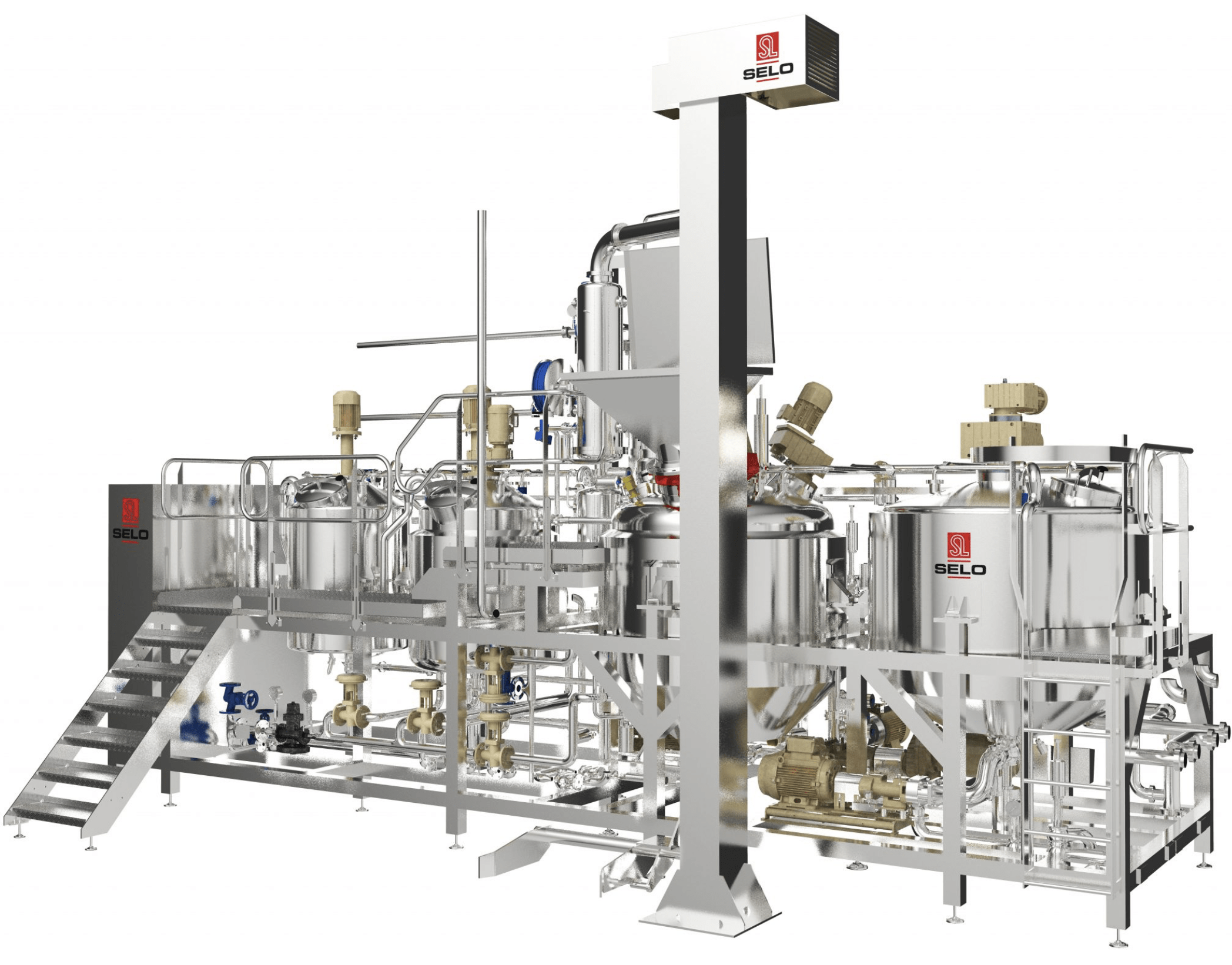

For a jam production line, you’ve come to the right place at Selo. We offer fully automated process and production lines for cooked, pasteurized, and refrigerated products such as jams, jellies, and marmalades. In the production of these delightful treats, we provide various installations tailored to your specific needs. Whether you aim for a completely homogeneous jam without fruit pieces or prefer to retain the distinctive fresh fruit chunks, Selo is ready to discuss your requirements and recommend the most suitable installation for your product.

With every installation we offer, the focus is on a hygienic design that meets the strict regulations of the food industry. When necessary, we adhere to the highest standards, such as the EHEDG guidelines, to ensure your products meet the utmost quality. At Selo, it’s all about providing high-quality production lines that meet your specific requirements, and we take pride in supporting you at every step of the process. Contact us today to discover how we can elevate your jam, jelly, and marmalade production to the next level.

JAM PRODUCTION LINES: WE GO FOR TOP QUALITY

Producing delicious jams, jellies and marmalades starts with precision and quality, and we at Selo understand that better than anyone. Our jam machines are designed to meet food safety standards AND so that you can make the most flavorful and consistent products. It is important to us that your production process is efficient and has short lead times. This allows you to achieve a high capacity.

At Selo, we understand that every jam production line has unique needs. That’s why our experienced engineers work closely with you to ensure that the production line perfectly matches your needs and specifications. In addition, we are constantly innovating and developing our machines to provide you with the latest technologies and automation systems, which also ensures that you can always maintain optimal and efficient production.

As icing on the cake, we at Selo offer the opportunity to pre-test your recipe and carry out trial batches in our own Technology Center. This way, you can be sure that your jam, jam and marmalade production meets the highest standards and that you are always delivering a consistently high-quality end product to your customers.

ADVANTAGES OF SELO’S JAM MACHINES

Our jam making equipment offer a range of benefits that will make your production process profitable. Our machines and equipment are designed with the highest quality standards in mind, resulting in reliability and durability you can rely on. But that’s not all. Here are some of the benefits our jam production line offers:

- High capacity and short process time: With our jam production line, you can produce large quantities of jam in a short time frame, resulting in an efficient production process and fast delivery.

- High percentage of whole fruit in the final product: Our facilities are optimized to maintain a high percentage of whole fruit in the final product, allowing your jam to retain its authentic taste and texture, with minimal damage to the product.

- Good color and taste: Thanks to the advanced technologies in our production lines, you can count on consistent color and taste in all your jam products.

- Ability to use 80% frozen fruit: We offer the flexibility to use up to 80% frozen fruit, allowing you to maintain your production throughout the year.

- Hygienic design, easy to clean, low maintenance: We pay great attention to hygiene so that cleaning and maintenance remain easy.

- Quick recipe changes without much waste: Our production lines are designed for quick and efficient recipe changes, allowing you to flexibly respond to new flavor trends and seasonal variations without waste.

- Both cool and hot filling possible: Our plants offer the possibility of both cool and hot filling, depending on your production needs.

- User-friendly: We have developed our concept so that your operators can work efficiently with minimal effort, saving time and reducing the likelihood of human error.

- Pre-test and run trial batches: At our in-house Technology Center, you can pre-test your recipes and run trial batches to ensure that your jam products meet the highest standards.

- Additional functionalities are possible: Aroma recovery and automatic brix control.

SELO’S APPROACH

At Selo, we always focus on quality, efficiency and strict hygiene requirements imposed by the Food and Consumer Product Safety Authority (NVWA). We bring that together with your specific needs and requirements. Do you want a fast and waste-free recipe changeover? Or the ability to fill both cool and hot and make this accessible to your entire team? We are happy to present the capabilities of our machines and invite you to experience it in our Technology Center.

Our engineering team translates all the information into a well thought out jam of customized machines. In our workshop, the production line is assembled with extreme precision, where each component is precisely placed and functionally assembled. Hardware and software come together here and undergo extensive testing to meet strict quality standards.

Then our technicians will come and carefully install the jam production line in your plant facility, making sure that everything works properly, exactly as discussed. Your operations team will receive hands-on training to become familiar with the new production line. Once everything is ready, production of your jam can begin.

SELO, THE SUPPLIER OF JAM PRODUCTION LINES

For years, Selo has been a progressive partner when it comes to designing, developing and realizing advanced jam production lines. As a leading manufacturer, we always offer a complete solution for your production process. From the design phase through to the commissioning of the systems and beyond. A complete team of experts in technology, automation, engineering, assembly, installation and after-sales is at your service. We not only offer standard solutions, but also custom production lines. You can count on our professional approach and high-quality services to make your project a success.

PRODUCING JAMS, JELLIES AND MARMALADES

Producing jam, preserves, and marmalade requires attention to several crucial aspects. Firstly, the quality of the ingredients used is essential. Fresh, high-quality fruits form the basis for flavorful products. Additionally, the correct use of sugar and pectin plays a significant role in the texture and preservation of flavor. Moreover, hygiene and adherence to food safety standards are crucial to ensure consistent product quality and to prevent foodborne illness.

When following market trends, it is important to consider the growing demand for healthier and more natural options. Consumers are increasingly seeking products with less sugar, no artificial preservatives, and a higher fruit content. Adapting to these trends can make your product more attractive to a wide range of consumers.

Additionally, offering a variety of flavors and unique combinations is crucial to meet the ever-changing consumer demands. Innovation in flavor profiles, such as incorporating herbs, spices, or even a touch of alcohol, can set your products apart from competitors. Understanding and responding to these factors helps you as a producer not only to meet consumer expectations but also to grow in the dynamic market for jam, preserves, and marmalade. By regularly conducting market research and gathering customer feedback, you can continually improve and align your offerings with the latest trends and preferences.