FISH PROCESS LINES

COOKING AND COOLING LINE FOR PREMIUM FISH PRODUCTS

Whether it concerns established A-brands or a starting producer who wants full support for a fish cooking and cooling line, Selo takes care of it. Worldwide we are active in new growth markets for Fish processing, such as Southern Europe, Southeast Asia and South America. But of course we also help established producers with optimization and flexibility.

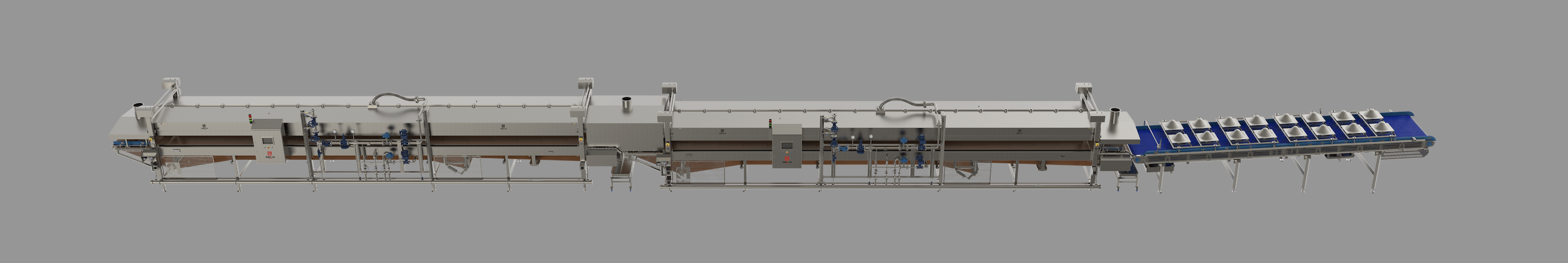

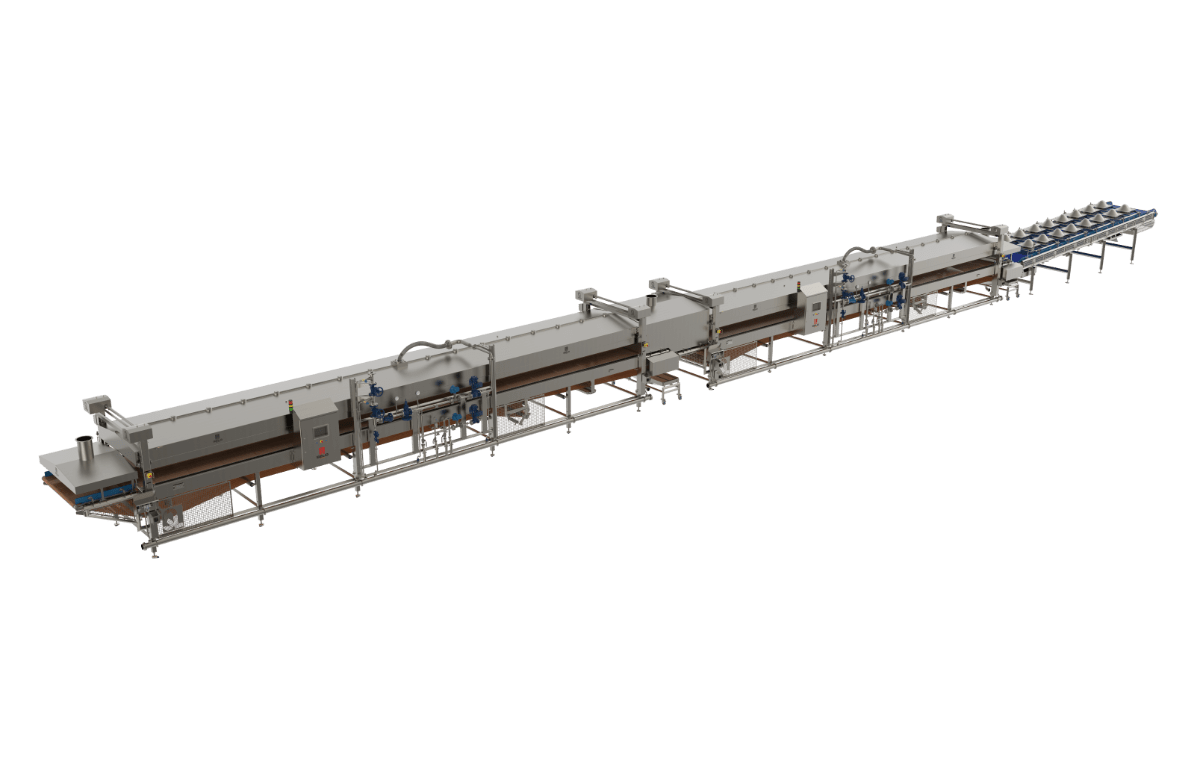

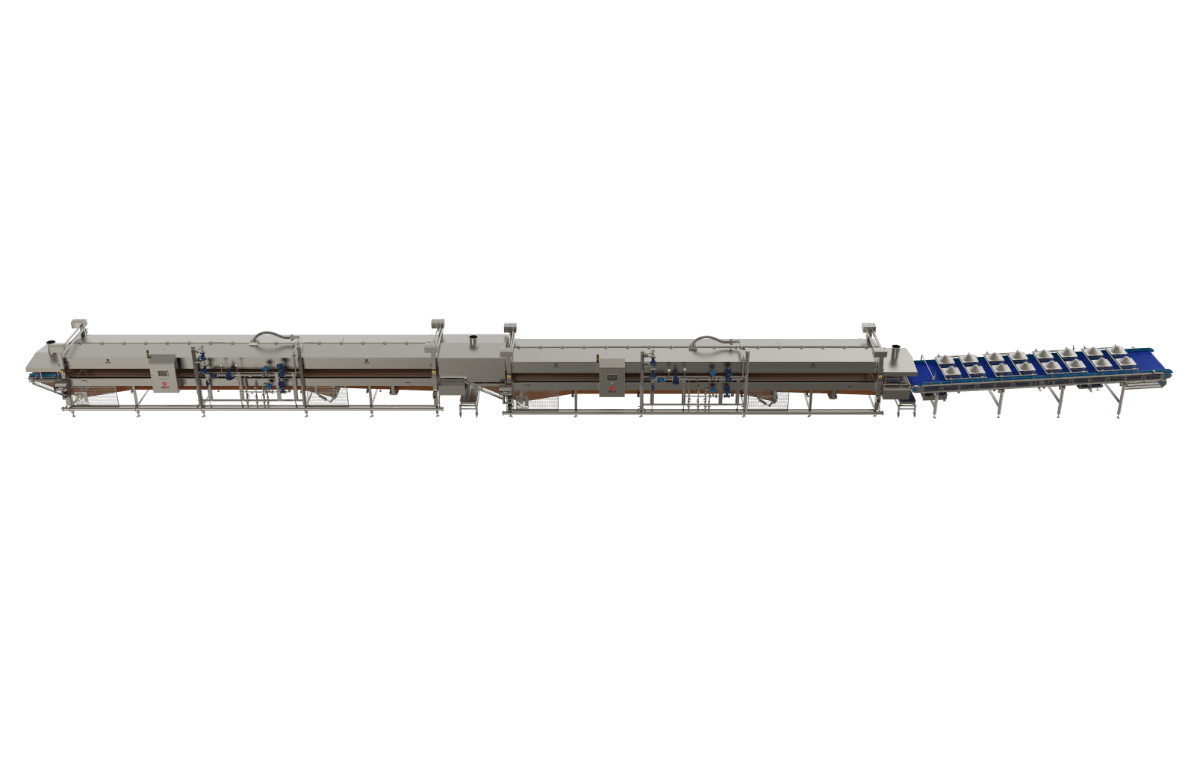

FISH PROCESS LINE

Continuous industrial steam cooking and cooling of fish, such as tuna, is an advanced and efficient method used in the food processing industry. This technology offers numerous benefits for preparing fish products and plays a crucial role in ensuring quality, food safety and nutrient preservation. There is also need for fewer operators due to more efficient production processes. Resulting in significant labor cost savings. Besides, fish oil can be preserved, filtered out and sold without the use of third parties or difficult filtering methods resulting in lucrative additional income.

KEY FEATURES SELO FISH COOKING AND COOLING LINE:

- Top-steam technology for even and efficient heat distribution

- Teflon belt ensures product doesn’t stick and prevents imprints on the product

- Precise temperature control for optimal cooking results

- Filter tank for collecting oil

APPLICATION

Preparation of fish fillets while preserving quality

Optimization of production processes, with capacities from 1000 kg per hour up to 4000 kg per hour

Flexibility in sizes and shapes to meet various market demands

BENEFITS

Consistent quality in fish processing

Tailored solutions for your production needs

Options for different market segments and capacities

Multiple applications; e.g. tuna, salmon, cod, white fish etc.

TESTING IN OUR TECHNOLOGY CENTER

Selo has an own technology center where we can pilot-scale test a wide variety of products and processes. A pilot size of steam tunnel is available in our technology center. The production line consists of a steam tunnel and a cooling/cutting combination.